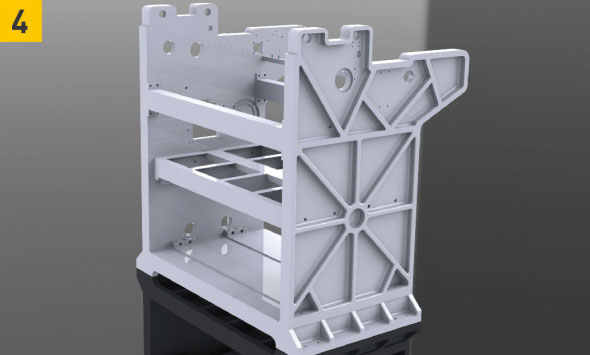

Automatic paper roll sheeter machine the high-quality nodular cast iron for the integration of design and through precision machining, improves the service life of the bearing parts,400 cuts/min low failure rate, and high yield efficiency.

1.Paper roll sheeter machine wall through finite element analysis, mechanical vibration analysis and optimization of the frame, uses the high quality nodular cast iron for the integration of design, and through precision machining, perfect the resonance phenomenon between the transmission components, More stable in high speed operation, improve the service life of the bearing parts.

2.Upper knife roller has the British cutter method to effectively reduce the load and noise during paper cutting, and to extend the life of the cutter. The upper knife roller is welded with stainless steel for precision machining, and is dynamically balanced during high-speed operation. Lower tool seat is made of cast iron integrally formed and cast, and then precision processed, with good stability

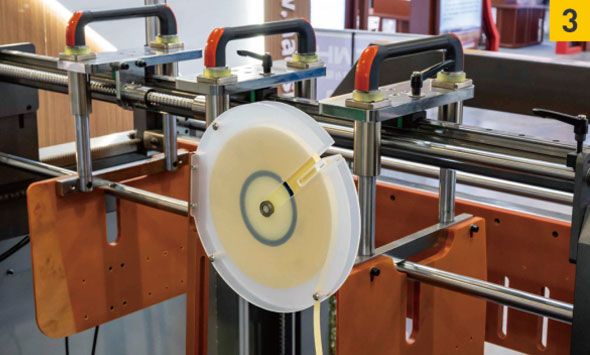

3.Three sets of pneumatic type slitting unit to have a high speed, smooth and powerless trimming and slitting, with quick adjustment and locking. High rigidity knife holder is suitable for 300m/min high speed slitting .

4.Touch screen controls are used to set and display sheet size, count, cut speed, delivery overlap, and more. The touch screen controls work in conjunction with a Siemens PLC.

HSC-D cutter uses the advanced technology of Taiwan and Britain.

Driven by AC servo motor.

Cutting paper stably in high speed.

Germany precise bearing and cutting knife assure the high precision.

Touch interface is simple to operation.

Reasonable inflection device ensures smooth of paper.

This machine is widely used in paper making, paper products processing and printing industry, and will improve efficiency and increase benefit for your company.

It's achievable for casting body to realize higher speed and more stability, thus significantly improve the service life of parts.

HSC-D is a simple but highly effective model which can reduce cost and increase benefit for your company.

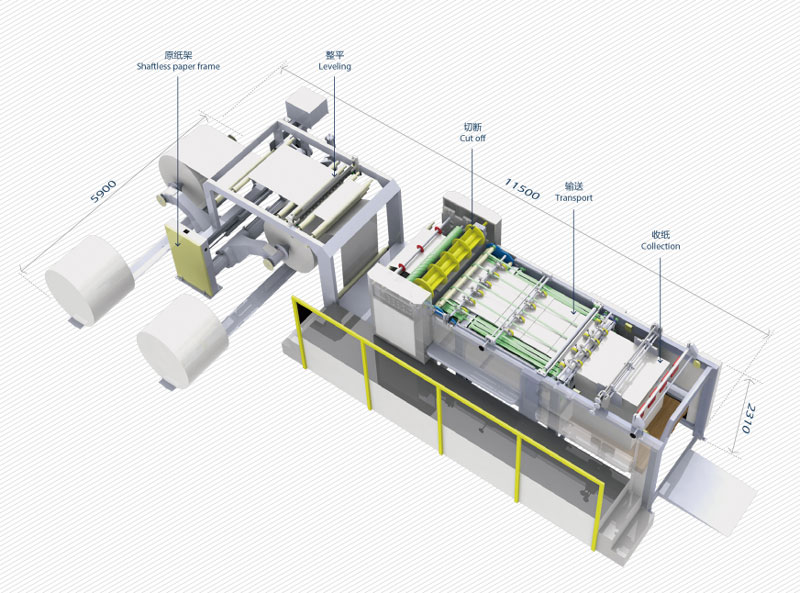

01. high-precision single knife cutting machine

02. prismatic adjustment system for paper

03. middle slitting and waste collection system

04. automatic counting and label inserting equipment

05. paper transporting equipment

06. automatic paper trimming and collecting machine

07. electrical controlling system

08. servo driver system

09. double lime pneumatic shaftless paper rack

|

CUTTING UNIT The upper knife uses British cutter method to reduce the load and |

|

|

CONVEYING OVERLAP PART A precision structure can adjust the synchronous deceleration wheel, |

|

AUTO COUNTING AND TAPINSERTER 1.Type: lnsert after counting precisely |

|

|

CASTING BODY The main machine wall is optimized through fnite element analysis, |

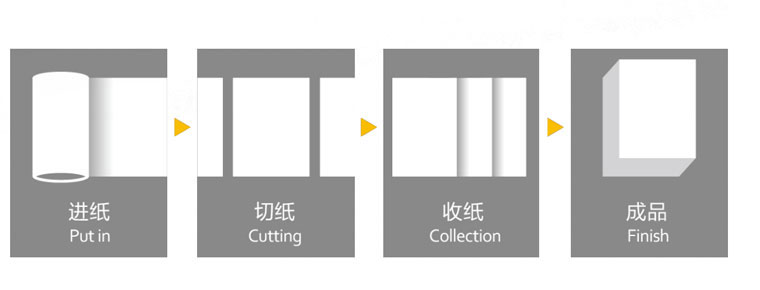

Mainly process including:Unwinding—Cutting—Conveying—Collecting.

|

Upper knife roll has the British cutter method to reduce The knife roll block with cast iron integrally molded casting, |

|

|

Dual position shaftless pivoting arm unwind stand 1)Max Reel Diameter: 1800mm |

|

Slitting knife Three sets of pneumatic type slitting unit to have a high speed, |

|

|

Motorized double decurler Effectively remove the curl of the roll to make the paper more flat, more conducive the paper roll tension stability, which enable this machine practically to run thick board till 200-500gsm . |

|

Delivery and Auto Jogger System Automatically goes down when paper piling up to a certain height. Conveyor system with mult-stage: from high speed to low speed. |

|

|

Electronic control YASKAWA servo,Siemens PLC,Schneider,Eaton, |

|

Delivery and Auto Jogger System The stacker table has three sides shake finishing function, |

|

|

Transport department The fast/slow speed belt is controlled by the stepless frequency converter, |

|

Auto counting and Automatic marking Type: Insert after counting precisely Auto -EPC (Edge Paper Control) Precision sensing nozzle which easily available and sensitive . Auto-tension control Put the paper roll diameter and paper weight number into touching screen, |

|

|

The main machine structure (Knife holder and holder stand) The main machine wall through finite element analysis, 1, AC Servo motor & encoder for cross knife |

2 reels unwinder (1 set EPC)

4 reels unwinder (3 sets EPC)

6 reels unwinder (5sets EPC)

| Model | HSC-1400D/1700D |

| Reference weight of cutting-paper | 50-550g |

| Model of cutting paper | The up knife cut reciprocally and the down knife is fixed |

| Cutting accuracy | +/-0.3mm |

| Gross weight | 14.000kgs/16.000kgs |

| Total power | 28kw |

| Power consumption | AC380V/220vx50HZ |

| Maximum cutting speed | 400cuts/min |

| Maximum cutting meter speed | 400m/min |

| Cutting length range | 400-1450mm/400-1650mm |

| Paper-piling height | 1400mm |

| Maximum scroll diameter | 1800mm(71"Max |

| Maximum paper-cutting width | 1400mm/1700mm |

| The format of slitting | 2sheet |

| The request for air compressor | Max.5.5kg/cm2x5m3/min |

|

1. |

Dust removal |

|

2. |

Color code tracking system |

Paper Roll Sheeter Machine is used to cut large paper rolls into individual sheets of the same size and further cut into multiple small sheets. It is widely used in printing, packaging, papermaking and other industries, and can effectively improve production efficiency and product quality.

In the printing industry, Paper Roll Sheeter Machine can accurately cut large printing paper rolls into individual sheets of required size, ensuring that the size and quality of each sheet of paper are consistent and meeting printing quality requirements. In the packaging industry, this kind of machine can cut large rolls of packaging paper into small sheets suitable for packaging boxes or bags, helping to improve the efficiency and accuracy of packaging production lines and reduce manual operations and error rates.

In addition, in the papermaking industry, Paper Roll Sheeter Machine can effectively control the size of paper, reduce waste, improve paper utilization, and also reduce energy consumption and environmental pollution during the production process.

|

|

|

|

A Paper Roll Sheeter Machine is an industrial device used to convert large paper rolls into smaller, more manageable sheets. This machine is often used in printing, packaging, papermaking and other industries to produce paper of various sizes from large mother rolls.

The process involves feeding a large roll of paper into a paper cutter, which then cuts the roll into individual sheets according to the required specifications. The machine usually includes components such as a feeding system, cutting mechanism, stacking unit and control system to ensure precise and efficient tableting.

Paper Roll Sheeter Machines are available in a variety of configurations to accommodate different types and sizes of paper rolls, and can be equipped with advanced features such as automatic tension control, precise length measurement and high-speed cutting capabilities. Plays a key role in streamlining production processes and improving paper processing efficiency.

Paper Roll Sheeter Machine can be divided into several types according to its different working principles and scope of application, mainly including the following:

1. Rotary Sheeters: This type of paper cutter uses a rotating blade to cut the paper roll and is usually suitable for thinner paper and higher production speed requirements. The rotary paper cutter can achieve high-speed cutting and precise positioning, and is suitable for printing, packaging and other industries.

2. Guillotine Sheeters: This type of paper cutter uses a cutting method similar to that of a guillotine, using a blade that moves up and down to cut the paper roll. Knife-type paper cutters are suitable for paper of various thicknesses and paper rolls of larger sizes, and are commonly used in paper processing, printing and other fields.

3. Slitter Rewinders: This type of equipment is mainly used to slit large rolls of paper or film materials into several strips and rewind them into small rolls or sheets. They are commonly used in the printing, packaging and labeling industries. .

4. Dual Rotary Sheeters: This type of paper cutter has two rotating blade systems, which can double-cut the paper roll at the same time, improving production efficiency and precision. It is suitable for occasions that require high-speed continuous cutting.

The above are some common types of Paper Roll Sheeter Machine. Each type of paper cutter has its specific applicable scenarios and advantages. When purchasing, you need to choose the appropriate type according to actual needs to ensure production efficiency and quality.

In industries ranging from printing and packaging to bookbinding and stationery manufacturing, the ability to cut large volumes of paper quickly and accurately is cr...

In the dynamic world of paper and packaging manufacturing, the demand for high-performance, automated equipment has never been greater. From converting jumbo paper r...

In today’s fast-paced printing and packaging industries, efficiency, precision, and automation are non-negotiable. Enter the automatic paper roll to sheet cutting ma...

Whether it is office paper, packaging boxes or book pages, most of the paper products we come into contact with every day are presented in the form of "single sheets...