Automatic paper roll-to-sheet cutting machine with auto stacker and trimmer, the feature is a cost-effective, high-speed cutter, high-precision models, has high-speed, smooth, powerless trimming and slitting functions, and has quick adjustment and locking functions. it is suitable for duplex paper, paperboard, grey paper, double-sided paper, cardboard, gray paper, kraft paper, etc.

1.Paper roll to sheet cutting machine upper knife roller has the British cutter method to effectively reduce the load and noise during paper cutting, and to extend the life of the cutter. The upper knife roller is welded with stainless steel for precision machining, and is dynamically balanced during high-speed operation. Lower tool seat is made of cast iron integrally formed and cast, and then precision processed, with good stability.

2.Three sets of slitting knife unit to have a high speed, smooth and powerless trimming and slitting, with quick adjustment and locking. High rigidity knife holder is suitable for 300m/min high speed slitting .

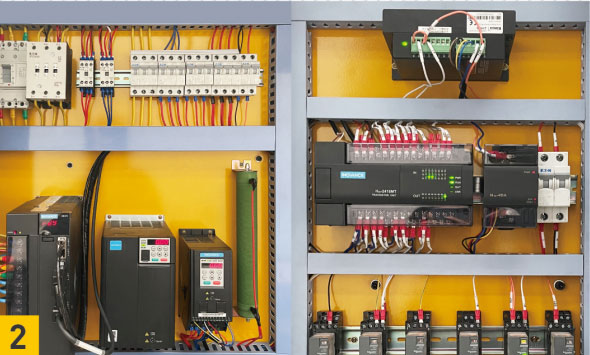

3.Touch screen controls are used to set and display sheet size, count, cut speed, delivery overlap, and more. The touch screen controls work in conjunction with a Siemens PLC.

HSC-B cutter uses the advanced technology of Taiwan and Britain.

Driven by AC servo motor.Cutting paper stably in high speed.

Germany precise bearing and cutting knife assure the high precision.

Touch interface is simple to operation.

Reasonable inflection device ensures smooth of paper

HSC-B is a simple but highly effective model which can reduce cost and increasebenefit for your company.

01. high-precision single knife cutting machine

02. prismatic adjustment system for paper

03. middle slitting and waste collection system

04. automatic counting and label inserting equipment

05. paper transporting equipment

06. automatic paper trimming and collecting machine

07. electrical controlling system

08. servo driver system

09. double lime pneumatic shaftless paper rack

|

CUTTING UINT The upper knife uses British cutter method to reduce the load and |

|

|

ELECTRIC CONTROL PART The man-machine interface and HZU processor, mainly used for the |

|

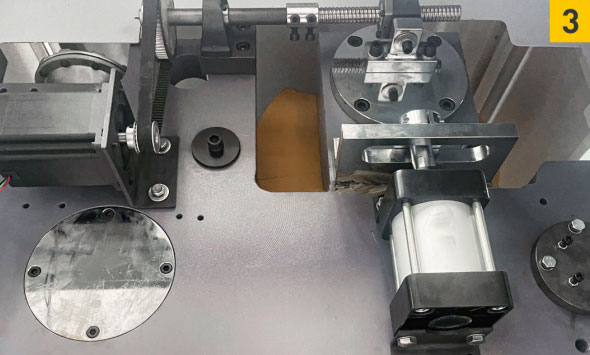

AUTOMATICALLY ADJUST THE ANGLE (PAPER ALIGNING SYSTEM) The stepper motor precisely controls the precision screw and adjusts |

|

|

MIDDLE SLITTING AND WASTE EDGE COLLECTING SYSTEM 1. The slitting knife at the top can be adjusted up and down, and the |

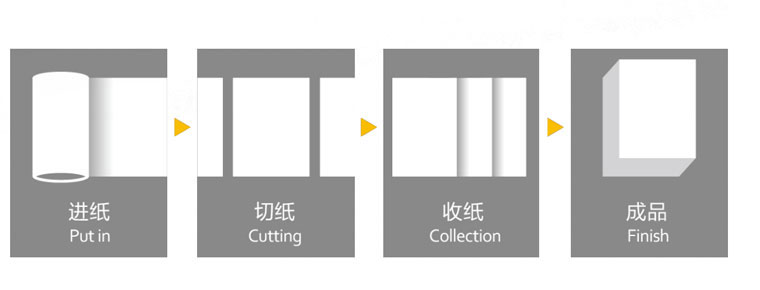

According to HOUSENG Product performance, the machine are mainly used for paper sheeting in Paper Mill, Printing House,Packaging and etc, mainly process including: Unwinding—Cutting—Conveying—Collecting.

|

Upper knife roll has the British cutter method to reduce the load and Rotary cutting knife is made of special alloy steel precision machining, |

|

|

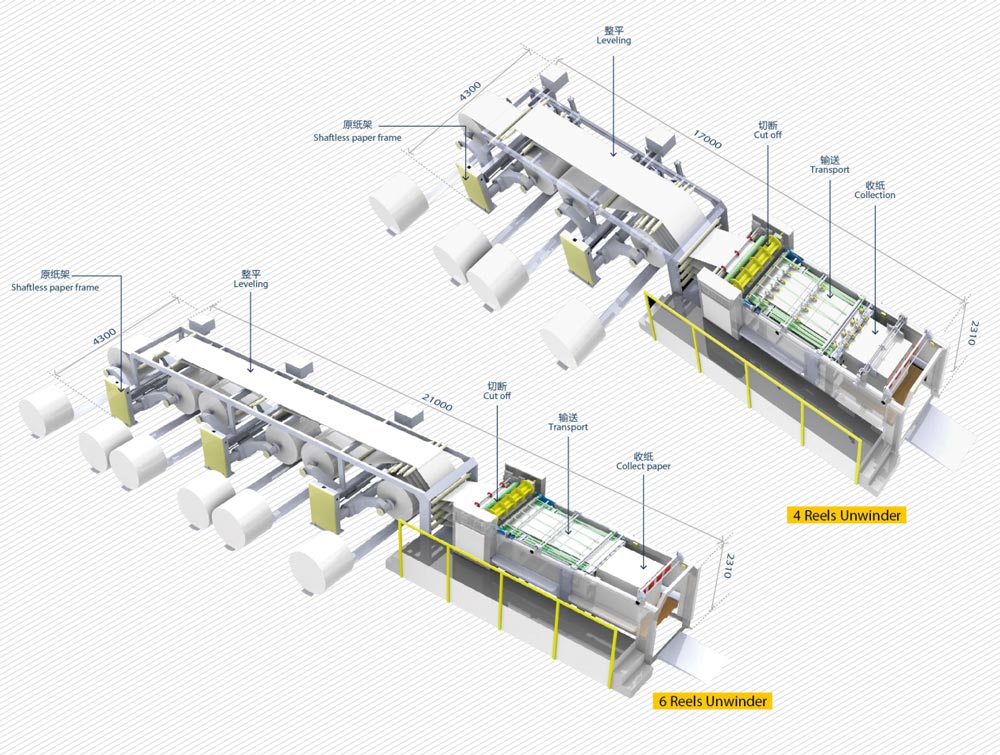

Dual position shaftless pivoting arm unwind stand 1)Max Reel Diameter: 1800mm |

|

Slitting knife Three sets of slitting knife unit to have a high speed, |

|

|

Motorized double decurler system Effectively remove the curl of the roll to make the paper more flat, |

|

Delivery and Auto Jogger System Automatically goes down when paper piling up to a certain height. Conveyor system with mult-stage: |

|

|

Electronic control INOVANCE Servo, INOVANCE PLC, Schneider, Eaton. |

|

Delivery and Auto Jogger System The stacker table has three sides shake finishing function, |

|

|

Transport department The fast/slow speed belt is controlled by the stepless frequency converter, |

|

Auto counting and Automatic marking Type: Insert after counting precisely Auto -EPC (Edge Paper Control) Precision sensing nozzle which easily available and sensitive . Auto-tension control Put the paper roll diameter and paper weight number into touching screen, |

|

|

Driving Motor system 1, AC Servo motor & encoder for cross knife |

|

2 reels unwinder (1 set EPC)

4 reels unwinder (3 sets EPC)

6 reels unwinder (5sets EPC)

| ITEM | PARAMETERS |

| Model | HSC 1100B/1400B/1700B/1900B |

| Reference weight of cutting-paper | 30-550g |

| Model of cutting paper | The up knife cut reciprocally and the down knife is fixed |

| Cutting accuracy | +/-0.3mm |

| Gross weight | 10.000kgs/13.000kgs |

| Total power | 28kW |

| Power consumption | AC380V/220vx50Hz |

| Maximum cutting speed | 300cuts/min |

| Maximum cutting meter speed | 300m/min |

| Cutting length range | 400-1650mm |

| Paper-piling height | 1400mm |

| Max. roll diameter | 1800mm(71”)Max |

| Maximum paper-cutting width | 1100mm/1400mm/1700mm/1900mm |

| The format of slitting | 2sheets |

| The request for air compressor | Max.5.5kg/cm2x5m3/min |

|

1. |

Blade -Tungsten Steel |

|

2. |

Cast Iron Main |

|

3. |

Imports Of Electrical Appliances |

|

4. |

Pneumatic slitting knife |

|

5. |

Dust removal |

|

6. |

Color code tracking system |

Paper Roll to Sheet Cutting Machine is a device specially designed to cut large rolls of paper into individual sheets of required size. This machine is widely used in printing, packaging, paper processing and other industries to improve production efficiency and accuracy.

The working principle of a paper roll-to-sheet cutting machine is usually to precisely cut the paper roll into the required size of paper through a set of knives or cutter wheels. It has functions such as automatic feeding, automatic cutting and automatic stacking, enabling efficient and continuous operations. The main applications of roll-to-sheet cutting machines include:

Printing industry: Cut large rolls of printing paper into standard size sheets for printing books, magazines, leaflets and other printed matter.

Packaging industry: Cut large rolls of packaging materials such as gray paper, kraft paper, etc. into packaging materials of required sizes.

Paper product manufacturing: Cut large rolls of paper into paper products such as cartons and paper bags of required specifications to meet market demand.

Stationery manufacturing: can be used to produce various stationery products, such as notebooks, letter paper, notes, etc. with precise cutting.

|

|

|

|

The working principle of the paper roll-to-sheet cutting machine usually includes the following main steps:

1. Introduce the paper roll: Introduce the large paper roll into the feeding system of the paper roll-to-sheet cutting machine. This may involve a series of tension control and positioning devices to ensure that the roll remains stable during the cutting process and can be delivered accurately.

2. Positioning and alignment: Paper roll-to-sheet cutting machines are usually equipped with a positioning system that can accurately position the paper roll to the cutting position to ensure cutting accuracy.

3. Cutting operation: Once the paper roll is accurately positioned, the cutting system will perform the cutting operation according to the preset parameters. Usually, a blade or die is used to cut the paper roll. The cutting method can be rotation cutting, pressure cutting or laser cutting.

4. Collection and stacking: The cut paper pieces will be sent to the paper collection system, and can be automatically stacked or stacked to facilitate subsequent packaging and transportation.

It is worth noting that different types of paper roll-to-sheet cutting machines may have some differences, such as differences in cutting methods, control systems and degrees of automation.

The paper roll-to-sheet cutting machine can reduce waste and waste during the paper cutting process and reduce the impact on the environment through precise cutting operations. At the same time, the paper roll-to-sheet cutting machine has a high degree of automation, which can improve production efficiency, reduce human resource consumption, and achieve a more efficient production method.

The advanced paper roll-to-sheet cutting machine also adopts energy-saving design and intelligent control system, which can reduce energy consumption, reduce energy consumption pressure on the environment, and conform to the concepts and requirements of modern environmentally friendly production.

In the realm of modern printing and packaging production, automatic paper sheet cutters stand as indispensable core equipment, and their paper type compatibility dir...

The right paper sheet cutter isn’t just a piece of equipment—it’s the backbone of consistent efficiency and product quality. Whether you’re handling packagin...

The printing industry thrives on precision—from the sharpness of text on a brochure to the alignment of graphics on a product box. Yet beyond ink and paper, another ...

In modern manufacturing and processing industries, sheet cutters have become essential equipment for handling various flat materials. Among them, high precision shee...