How Does a Sheeter Machine Influence Modern Industry and What Technologies Enhance Its Performance?

Paper is an indispensable material for modern industry and everyday life. Whether it is used for writing, printing or packaging, paper is produced and processed with one key piece of equipment - the paper roll cutter. This equipment plays a vital role in paper production, from large rolls of paper to the precise cutting of paper to the required size, the accuracy of the process directly affects the quality of the final product.

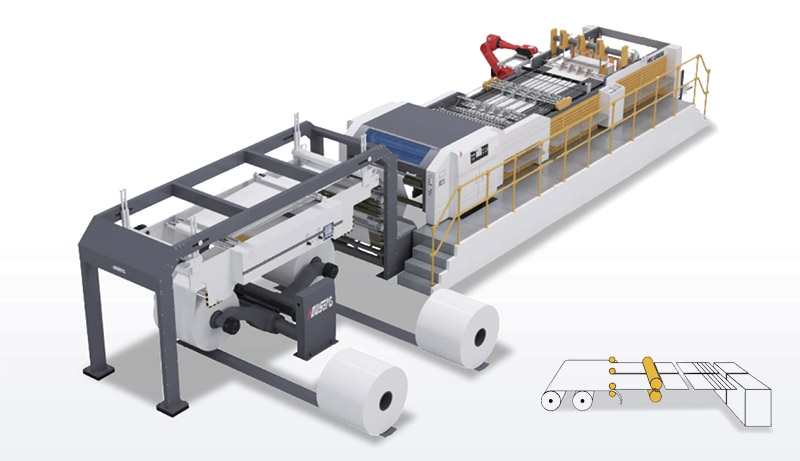

The basic principle of a Automatic Paper Roll To Sheet Cutter Machine

The working principle of a Paper Roll To Sheet Cutter Machine is simple and efficient. Its main function is to cut large rolls of paper into smaller pieces of a predetermined size. The process usually consists of the following steps:

1. Paper roll feeding: The paper roll is placed into the feeding area of the machine. The diameter and width of the paper roll can be adjusted as needed to accommodate different sized paper rolls.

The embedded double helical knife design, developed exclusively for HOUSENG's Automatic Paper Roll To Sheet Cutter Machine, saves cutting seams and allows for an additional 150-200 sheets per ton of paper.

2. Unfolding and Tensioning: The paper roll is unfolded and tensioned by a tensioning device to ensure that the paper remains stable during the cutting process and avoids creasing or tearing.

3. Cutting: The cutting device in the machine cuts the paper precisely to the required size. There are various cutting methods, such as blade cutting, laser cutting, etc., in order to adapt to different thicknesses and materials of paper.

4. Paper collection: The cut paper is collected in a designated collection area, usually via a conveyor system that transports the paper to the next processing step.

Key technologies of the roll to cutter

1. Precision Control System: Modern roll to cutter machines are equipped with advanced computerized control systems that precisely control the cut size, speed and position to ensure that the size of each sheet is consistent. 2.

2. automation features: in order to improve production efficiency, many paper cutters are equipped with automation features, including automatic paper loading, automatic adjustment of cutting size and automatic cleaning. These features greatly reduce the need for manual operation.

3. Knife technology: High-quality knives are key to ensuring effective paper cutting. The cutter knife needs to be maintained and replaced regularly to maintain the sharpness and accuracy of the paper cutting.

4. Safety design: Paper roll to paper cutting machines are usually equipped with various safety devices such as emergency stop buttons, guards and sensors to ensure the safety of the operator.

Application Areas of Paper Roll Cutting Machine

Paper sheeters are widely used in a variety of applications, including but not limited to

1. Printing industry: for cutting printed rolls of paper into standard sized printed sheets.

2. Packaging industry: for cutting large rolls of paper into wrapping paper.

3. Office supplies: used to cut rolls of paper into various sizes of office paper, such as printing paper and copy paper.

4. paper making industry: used to produce various paper products, such as paper bags, paper boxes and so on.

Considerations for choosing a paper roll cutter

There are several key factors to consider when choosing a paper roll cutter:

1. cutting accuracy: according to the requirements of the final product, choose a machine with high cutting accuracy to ensure the accuracy of the paper size.

2. production capacity: according to the production requirements to choose the appropriate capacity and speed to improve production efficiency.

3. Equipment Maintenance: Choose equipment that is easy to maintain and clean to reduce long-term operating costs.

4. energy efficiency: choose equipment with low energy consumption to help reduce operating costs and minimize environmental impact.

Conclusion

The High Speed Paper Sheeter Machine plays an irreplaceable role in the production of paper products. From large rolls of paper to small, precisely cut sheets, it ensures the quality and consistency of paper for all types of industrial and everyday needs. The Double-spiral Roll To Sheet Paper Sheeting Machine from HOUSENG guarantees perfect cutting quality, with neat paper output, no scratches and no burrs. It can be directly used for printing, realizing efficient production and saving labor costs.

With the advancement of technology, modern roll to paper cutter is constantly innovating and upgrading to provide more efficient and precise solutions for various industries. Whether it is a large printing plant or a small paper mill, the paper roll to paper cutter is quietly supporting the prosperity of the paper products industry behind the scenes.