Rotary Sheet Cutter Machine Overview,Working Principle,Selection Guide

The development trend of the packaging and printing manufacturing industry has promoted the development trend of the paper cutter manufacturing industry. The Rotary Sheet Cutter Machine, which is widely used in life and work, mainly cuts paper by using blades and pressure. This article tells you what is Rotary Sheet Cutter Machine, working principle, buying guide.

Rotary Sheet Cutter Machine Overview

Rotary Sheet Cutter Machine is a cutting machine that can cut sheets of material into various shapes and sizes using a cutting blade. It is commonly used in manufacturing and production lines to cut materials such as paper. This machine has become increasingly popular in recent years due to its efficiency and cost-effectiveness.

There are several features and benefits of a Rotary Sheet Cutter Machine:

Speed and Efficiency - Rotary Sheet Cutter Machines can cut sheets of material quickly and efficiently, reducing production time and labor costs.

Automatic Operation - These machines typically have automatic feeding and cutting functions, reducing the need for manual intervention and increasing productivity.

Versatility - These machines can cut a wide range of materials, making them suitable for a variety of different production processes.

Safety Features - Many Rotary Sheet Cutter Machines have safety features such as blade guards and sensors to prevent injury to operators.

Easy Maintenance - These machines are typically easy to maintain and require minimal downtime, ensuring continuous production.

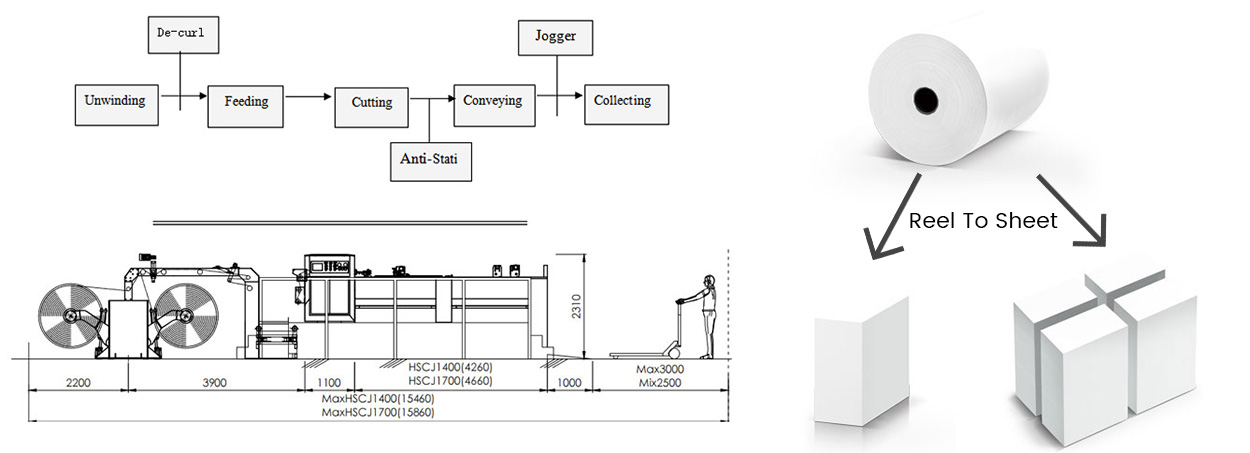

Rotary Sheet Cutter Machine Working Principle

rotary sheet cutter machine works by rotating a blade rapidly while the sheet of material is fed through the machine. The blade cuts the sheet of material based on the pre-set cutting pattern. There are various types of rotary sheet cutter machines available in the market, each with its own specific features and working principles.

The machine usually consists of a cutting unit, a drive unit, and a support unit. The cutting unit includes the blade that rotates at high speed. The drive unit provides power to the blade for rotation and can be manual or powered by an electric motor. The support unit supports the sheet of material and can include various types of feeders to ensure even feeding and positioning of the material.

During operation, the operator places the sheet of material on the support unit and presses a start button or switch. The blade then rotates at high speed, and the material is fed through the machine according to the pre-set cutting pattern. The blade cuts through the material based on its hardness and thickness, creating a precise cut.

The working principle of the rotary sheet cutter machine is based on physics principles such as friction, air resistance, and blade speed. The blade speed and feed speed are carefully controlled to ensure a clean and precise cut every time.

Please note that this is a general explanation of the working principle of a rotary sheet cutter machine and not a detailed technical specification. For specific information, it is recommended to consult the manufacturer or relevant technical resources.

Rotary Sheet Cutter Machine Selection Guide

Cutting Capacity: Consider the maximum thickness and width of the material you need to cut. Make sure the rotary sheet cutter machine can handle the size and thickness of your materials.

Speed and Precision: Look for a machine that offers high cutting speed and precise cutting capabilities to ensure efficient and accurate cutting.

Blade Type: Check the type of blades the machine uses. Different materials may require different types of blades for optimal cutting performance.

Safety Features: Ensure that the machine has safety features such as blade guards, emergency stop buttons, and safety interlocks to prevent accidents and injuries.

Ease of Use: Choose a machine that is user-friendly and easy to operate, with intuitive controls and clear instructions for setup and operation.

Durability and Maintenance: Consider the build quality and durability of the machine, as well as the ease of maintenance and availability of replacement parts.

Price and Value: Compare the price of the machine with its features and capabilities to ensure you are getting the best value for your investment.

Customer Support and Warranty: Check the manufacturer's reputation for customer support and the warranty offered for the machine to ensure you have support in case of any issues.