HSC-D is a simple but highly effective model which can reduce cost and increase benefit for your company.

01. high-precision single knife cutting machine

02. prismatic adjustment system for paper

03. middle slitting and waste collection system

04. automatic counting and label inserting equipment

05. paper transporting equipment

06. automatic paper trimming and collecting machine

07. electrical controlling system

08. servo driver system

09. double lime pneumatic shaftless paper rack

|

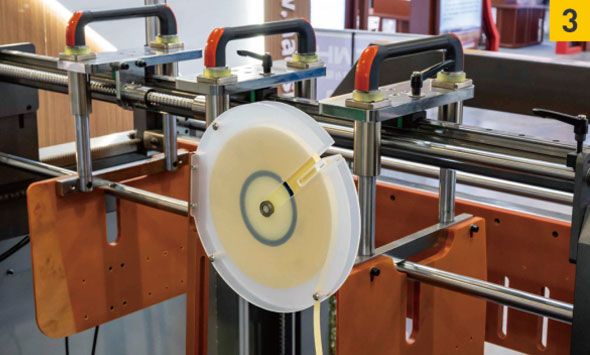

MIDDLE SLITTING AND WASTE EDGE COLLECTING SYSTEM 1. The slitting knife at the top can be adjusted up and down, and the bottom side is fxed, 2. Use vacuum blower andY-exhaust pipe to discharge waste |

|

|

CONVEYING OVERLAP PART A precision structure can adjust the synchronous deceleration wheel easy to operate, |

|

AUTO COUNTING AND TAP INSERTER 1.Type: lnsert after counting precisely 2.Function: |

|

|

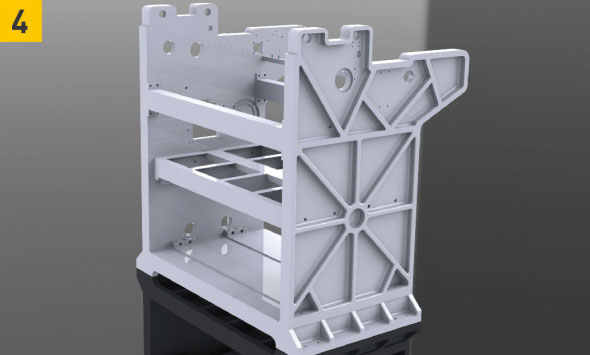

CASTING BODY The main machine wall is optimized through fnite element analysis to |

| ITEM | PARAMETERS |

| Model | HSCJ 1100D/1400D/1700D/1900D |

| Reference weight of cutting-paper | 50-550g |

| Model of cutting paper | The up knife cut reciprocally and the down knife is fixed |

| Cutting accuracy | +/-0.3mm |

| Gross weight | 14.000kgs/16.000kgs |

| Total power | 28kW |

| Power consumption | AC380V/220vx50Hz |

| Maximum cutting speed | 400cuts/min |

| Maximum cutting meter speed | 400m/min |

| Cutting length range | 400-1650mm |

| Paper-piling height | 1400mm |

| Max.roll diameter | 1800mm(71")Max |

| Maximum paper-cutting width | 1100mm/1400mm/1700mm/1900mm |

| The format of slitting | 2sheets |

| The request for air compressor | Max.5.5kg/cm2×5m3/min |

In industries ranging from printing and packaging to bookbinding and stationery manufacturing, the ability to cut large volumes of paper quickly and accurately is cr...

In the dynamic world of paper and packaging manufacturing, the demand for high-performance, automated equipment has never been greater. From converting jumbo paper r...

In today’s fast-paced printing and packaging industries, efficiency, precision, and automation are non-negotiable. Enter the automatic paper roll to sheet cutting ma...

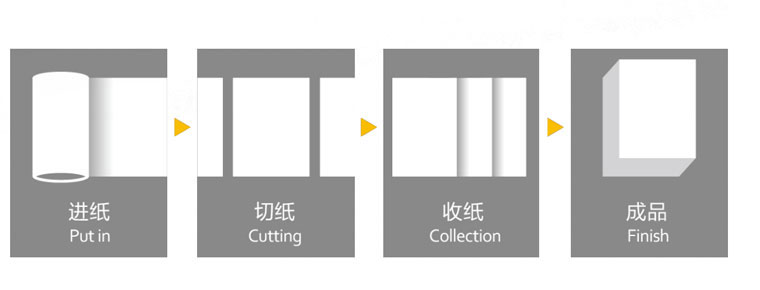

Whether it is office paper, packaging boxes or book pages, most of the paper products we come into contact with every day are presented in the form of "single sheets...